Product Lists

Hot Product

Pellet Feed Production Line

français русский Español portugués

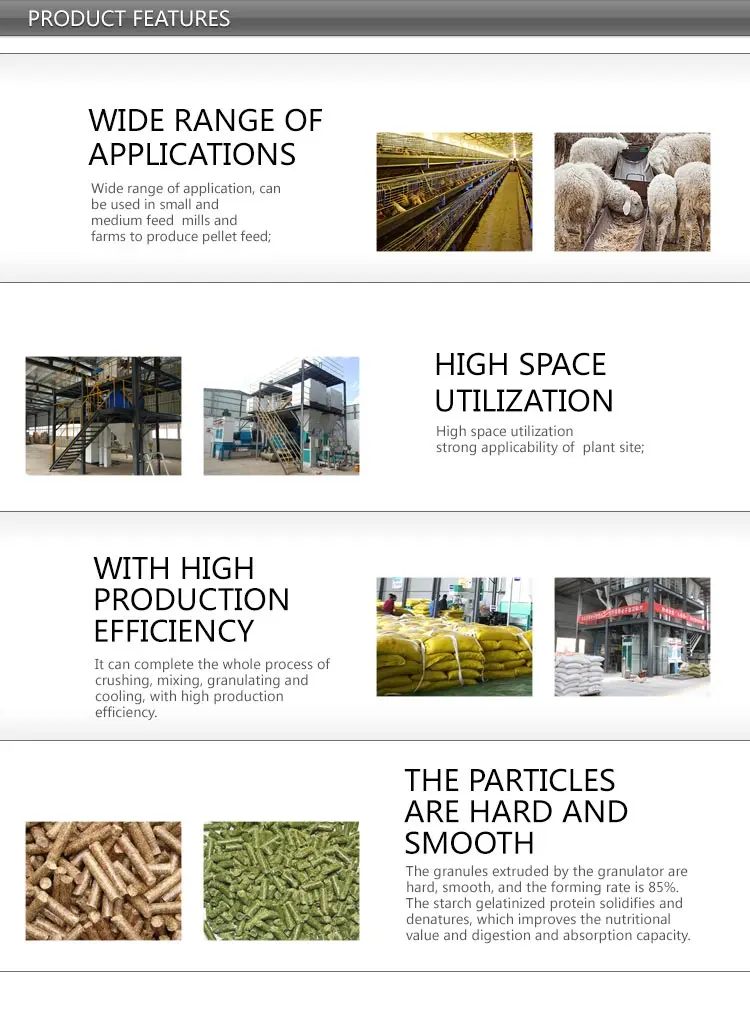

Features:1: Grinding, mixing, pelleting, cooling, crumbling and packaging are integrated.

2: reasonable process, compact structure and small area occupation, low investment and quick returns.

3: It’s suitable for livestock, poultry and aquatic product farms to produce feed the raw materials can be wheat, corn, maize, bean, rice husk.

4: There are manual and fully-automatic complete feed set.

5: particle constituents of uniform, the surface is smooth, diameter can transform between 1.5-6mm (die) needs to be replaced, length can be adjusted between 5-20mm, and the particle density, for easy storage and transport, suitable for a variety of cultural objects in different period of need.

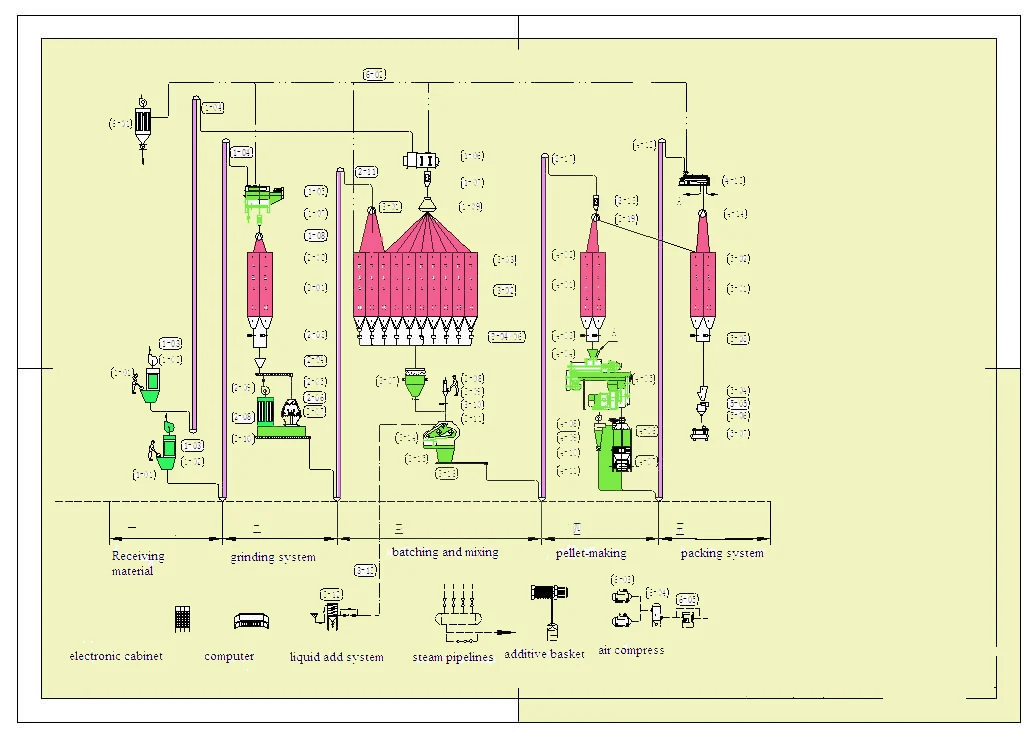

Continuous and reasonable process flow in our Pellet Feed Production Line:

l Raw material storage system of poultry feed plant: Silo

l Pre-cleaning system of poultry feed plant: Pre-cleaner

l Crushing system of poultry feed plant: SFSP model Hammer Mill

l Proportioning system of poultry feed plant: Batch weighed, Rotary distributor, Batch bins

l Mixing system of poultry feed plant: Mixer

l Pelletizing system of poultry feed plant: Ring Die Pellet Mill

l Cooling system of poultry feed plant: Cooler, cyclone

l Sieving system of poultry feed plant: Grade sifter

l Packing system of poultry feed plant: Packing scale

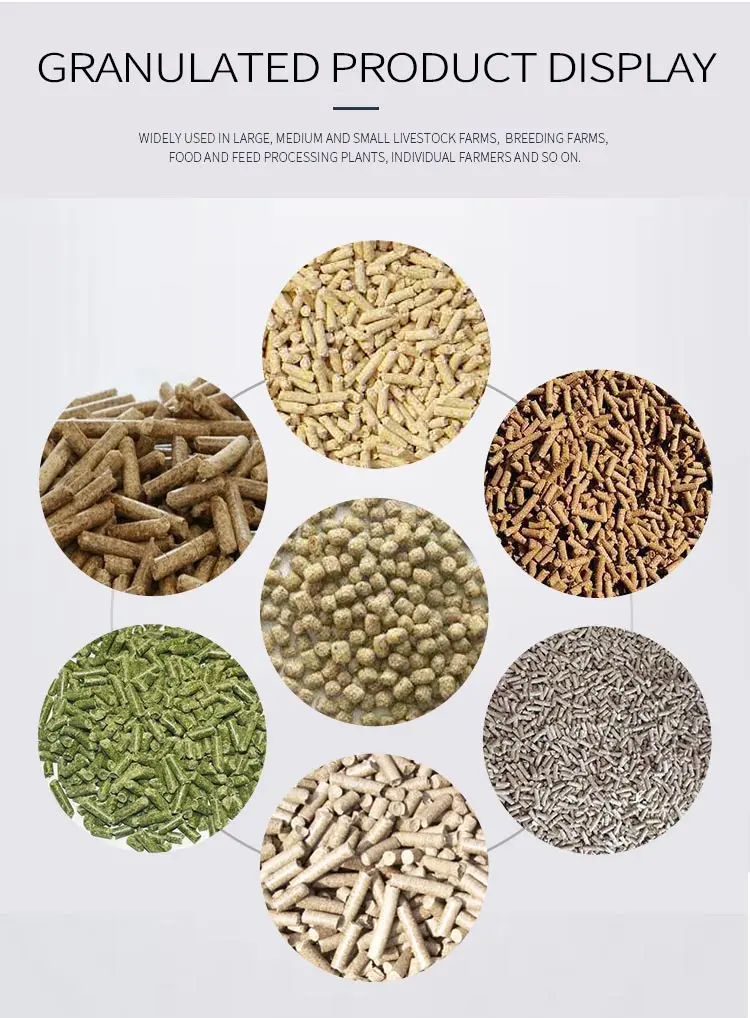

a. For pig, the pellet diameter is usually ø3.5-6.5mm.

b. For cattle, the pellet diameter is usually ø4.5-8mm.

c. For chicken, pellet diameter is usually ø3.2mm.

d. For fish, pellet diameter is usuallyø2.0, ø2.5, ø3.0mm.

e. For shrimps, pellet diameter is usually ø1.0-ø3.5mm.

Pellet length is customized.

1,Raw material receiving and cleaning process

The raw materials are transported to the factory, and after weighing and weighing in the ground, the materials are manually unloaded to the corresponding storage space of the raw material warehouse for stacking.

2,the crushing process:

At the time of production, the material to be pulverized is manually transported to the raw material feeding port, the material is weighed, and the pulverizer and corresponding equipment are started. The material enters the pulverizer through the air transportation pipe, and the pulverized material directly falls into the mixing chamber of the mixer for mixing.

3, the mixing process:

The material enters the mixer and begins to mix. After mixing, the material flows through the discharge port to the screw hopper feed hopper, and enters the granulation bin through the spiral hoist.

4,granulation, cooling process:

The mixed material enters the feeder and the modulator through the granulating bin, enters the granulator for granulation, and after granulation, the winder enters the cooler to start cooling, and the cooled material is sieved to the finished material through the vibrating sieve. Directly into the bag for packaging.

If you don't enough budget ,cooling system is optional , you can put finished feed under sun for cool and dry.Above is completely animal feed pellet production line ,use ring die pellet machine.

Whole feed set includes raw material feeding and pre-cleaning,grinding system,pellet system,packing system.We equip liquid adding system for it,it can add moisture,molasses, lipid in feed. Designed simply from crusher to packing machine , contains crushing, mixing, pelletizing , screening and packing parts. such as crusher, mixer, pellet mill, cooler ,screener, packing machine and all bins, conveyors ect .

In raw material receiving and precleaning system,we use pulse dust collector,granular drum sieve,powder sieve,tubular magnet and conveyor equipment to clean up impurities of grain,and convey raw material to grinder to be crushed.

In mixing system,we use double-shaft high efficient paddle mixer,which could mix material with high homogeneous mixing degree (CV≤3~5%) and short time(45~60s).The spraying system (spray nozzle & fittings) is on top of mixer can meet light and heavy bulk density materials mixing,improve the liquid atomizing and prevent from agglomerating

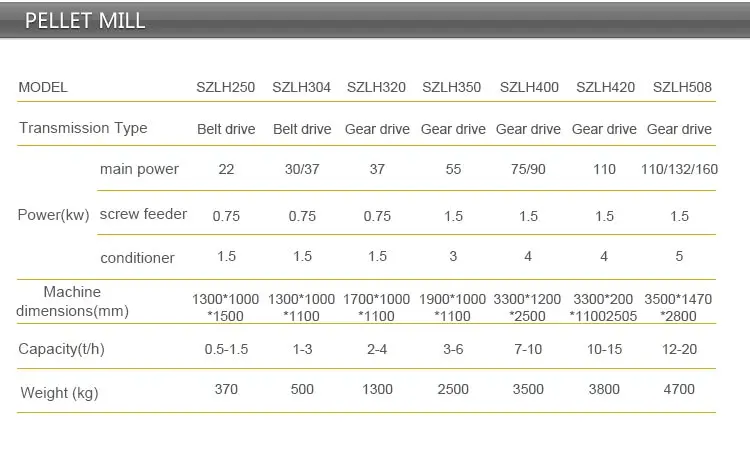

In pelleting system,we adopt our key product SZLH ring die pellet mill.It makes 2-8 mm diameter feed pellets. such as 2-4mm diameter chick feeds and pig feeds.1.5-3mm fish feed,2-5mm rabbit feeds,4-8mm cattle or sheep feeds.The machine mosaic rotating roller and large diameter ring dies can make materials fully cured and pellets smoother.The formation rate can reach 98% and the friction can down to the bottom.Key parts are made by our CNC system,through high technical heat treatment,which is high precision and quality.Pellet feed will be delivered into counter-flow cooler to be cooling down after being pellet,then enter into crumbler.Big pellet will be crushed to small pellet,small pellet and powder will enter into pellet mill again to be made into pellet by rotary screener.

In packing system,after crushing by crumbler,appropriate size pellet feed enter into finish product bin to be packed. We equip automatic packaging machine and bag sewing machine to weigh and pack final product.

In auxiliary system,we equip air compressor and steam boiler according to quantity of compressing air whole set need and capactiy of pellet mill.If the mixer is installed in a relatively high position,we equip additive basket to ensure accurately put the additive.

1.Are you manufacturer,yes or not?

Answer:Yes,we have been feed machine manufacturer for 23 years,and it will be longer.Now we are capable of producing not only feed machines but also biomass machines and mineral stone processing machines.

2.Can you accept the customized plan? Can you simplify my plan for reducing costs?

Answer:Of course,our brilliant engineers are waiting for it all the time.

3.What's your MOQ?

Answer:Generally speaking,one is okay,but larger quantity ,lower price.

4.What do I need to know to build a feed processing plant?

Answer:You just need figure out the following questions:

(1)What animal do you want to feed? the animal amount?This is used for confirming the production capacity and feed type.

(2)What raw materials you have?material size?material moisture?

(3)Any special demand?

Our engineers will provide customized plan for you. Thank you for your trust. Welcome to contact with us at any time!

If you need our machine please advice the following detail information:

1, The capacity you need per hour?

2, Your raw materials?

3,The moisture of your raw material?

What's your raw material,feed formula and capacity requirements?We can customize production line according to your demands.

![[field:title/]](/uploads/200928/1-20092P95Z2616.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)

![[field:title/]](/uploads/200429/1-20042915210J35.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)