Product Lists

Hot Product

1 ton pellet feed production line

Description for feed making plant

|

|

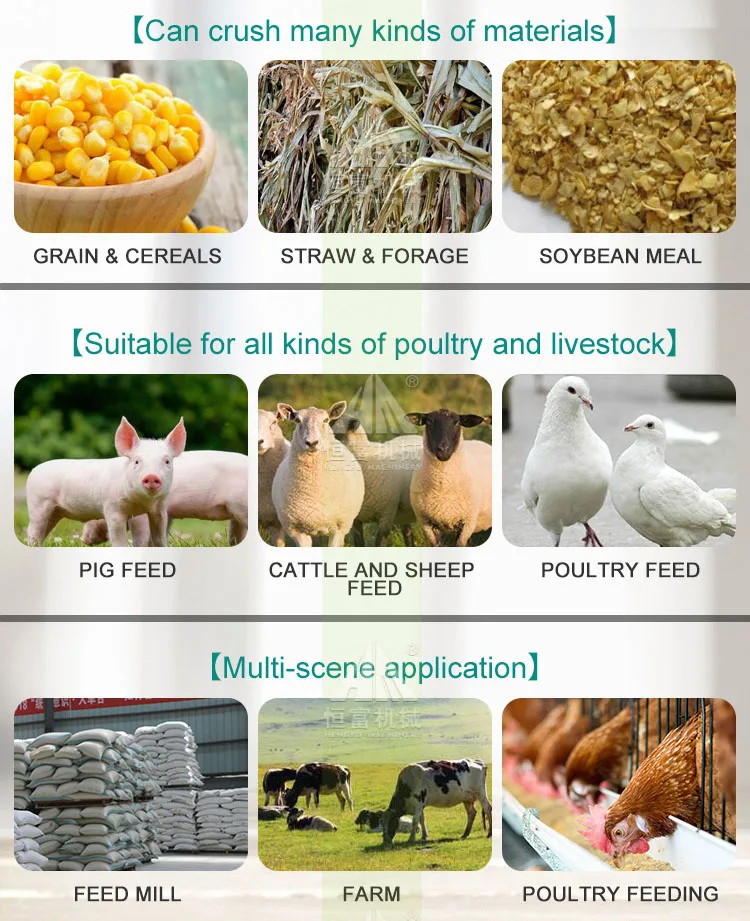

| This animal feed pellet production line can be used for processing livestock, poultry and aquatic feed pellets, which is specially suitable for big feed factory, breed farms. It has the better raw material versatility, which can be suitable for pelletizing many kinds of raw material, such as corn, broom corn, wheat, beans, oil seed meal and other materials . And also, this manufacturing plant for animal feed has the features of low energy consumption and high production efficiency for larger profits. | |

|

|

| Capacity | Pellet feed from 100-1000 kg/h |

|

|

Advantages of the flat die pellet line

1. Simple structure. |

|

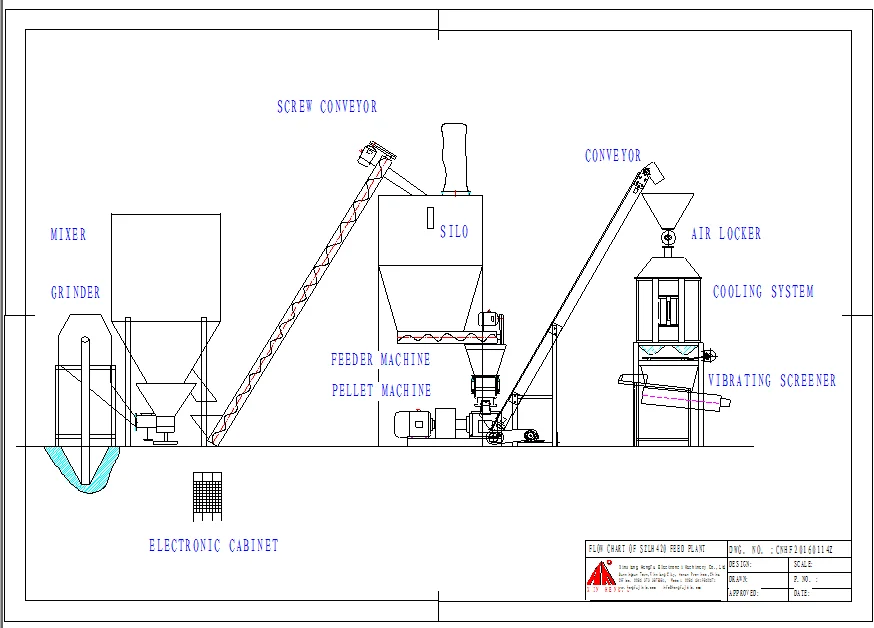

| ——Main equipment | |

|

9FQ MULTIFUNCTION GRINDER

It widely used in all kinds of crop stalk, cotton firewood, rice straw, clover, peanuts shells, rice husk cotton seed fur, also use for corn, weeds, soybean, maize, grain, ect. |

|

9HT VERTICAL MIXER

Large capacity with the low power consumption: one batch can be 500/1000kg. Easy control, low cost, good performance |

|

9KLP FLAT DIE PELLET MILL

Low noise, low energy consumption, continuous production and easy operation. Diesel engine and motor power are available |

|

SKLN COUNTER FLOW COOLER

The latest octagonal cooling box design, no cooling dead ends. The use of closed feeder feed, into the air area, cooling effect is significant. |

|

AUTOMATIC PACKAGING MACHINE

|

|

Electric control cabinet

|

| Some equipment can be replaced or removed according to different configurations | |

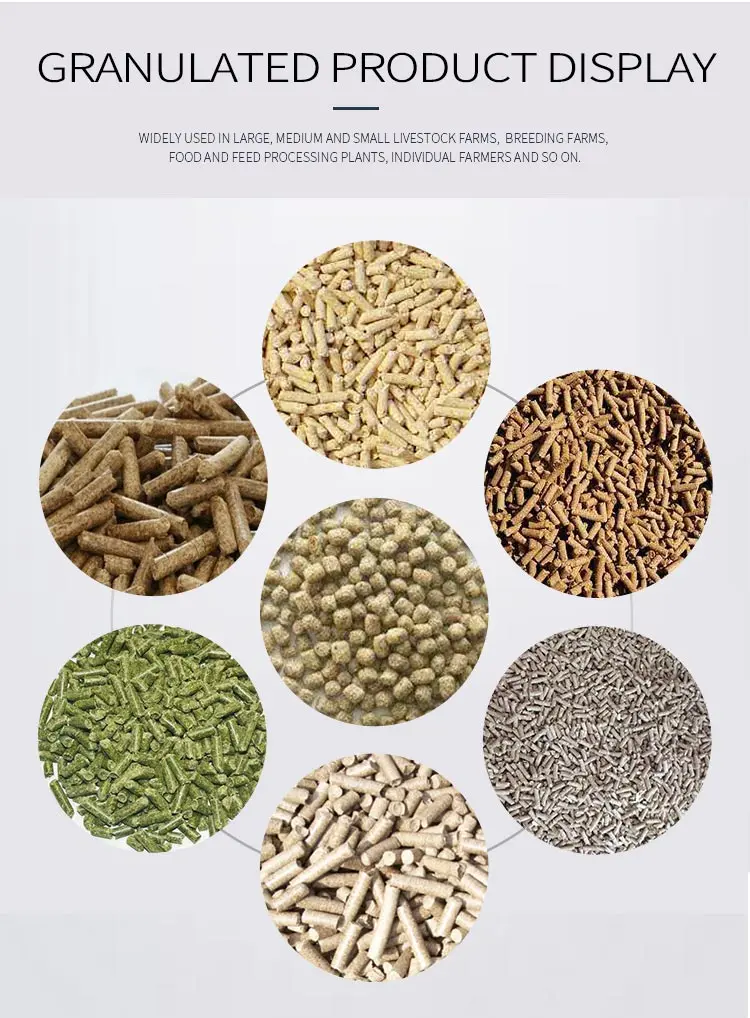

| ——Final product | |

|

|

|

a. For pig, the pellet diameter is usually ø3.5-6.5mm. Pellet length is customized. |

|

| Small feed mill plant display | (Different configuration forms) |

|

|

|

|

![[field:title/]](/uploads/200429/1-200429152356308.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)

![[field:title/]](/uploads/200429/1-200429160330427.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)